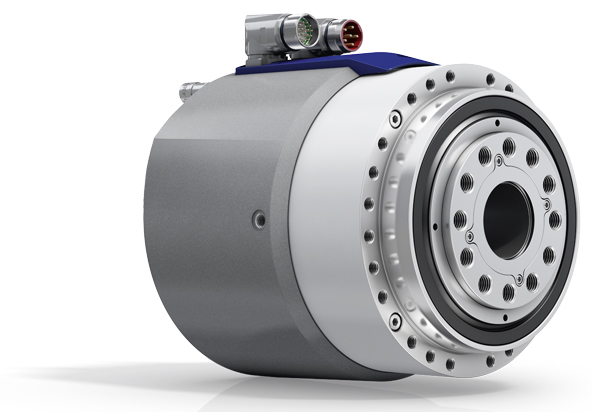

Thanks to the Galaxie® GS, workpieces can now be tilted and held with absolute precision

Precision machining specialists Peiseler have integrated WITTENSTEIN’s Galaxie® GS215 hollow-shaft gearbox into the drive system of their new ZASG 400 two-axis rotary tilt table. The result is a rotary tilt unit combining a compact design with high economic efficiency that positions workpieces fast and extremely accurately ready for machining.

When precision matters, Peiseler delivers

Changing, tilting, turning and rotating – around 170 people at Peiseler’s two factories in Remscheid and Morbach (Germany) manufacture dividing heads and rotary tilt tables in leading-edge technology to enable highly precise and dynamic positioning of workpieces in machine tools. These solutions are ideal wherever space is limited; depending on the model, workpieces weighing anything from a few grams to 50 tons can be moved and held absolutely precisely. The company can look back on more than two centuries of experience in the engineering industry – over 55,000 Peiseler-made dividing heads and rotary tilt tables are currently in action worldwide.

+49 7931 493-18860