Big Moves for Automatic Fiber Placement Systems

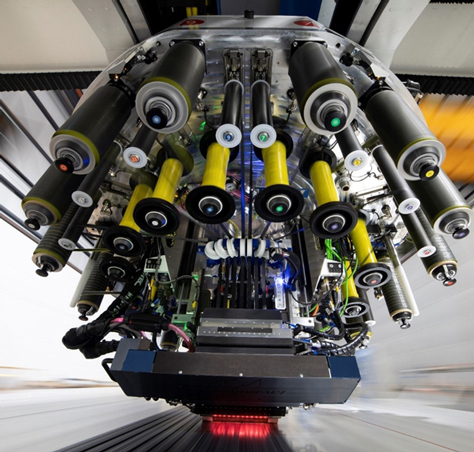

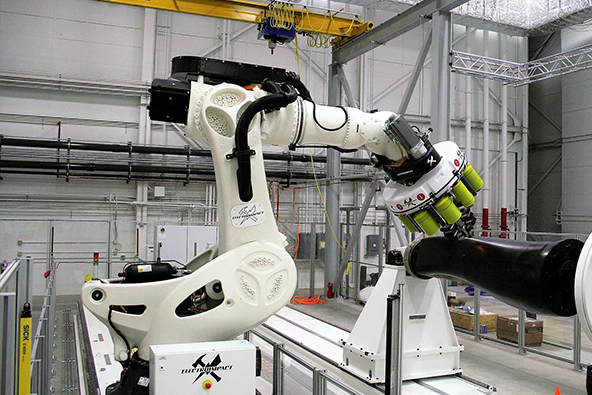

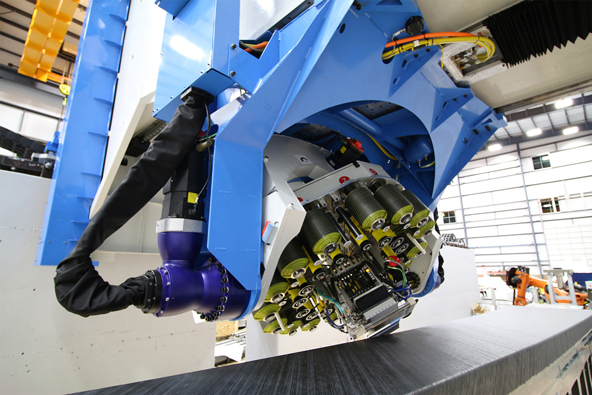

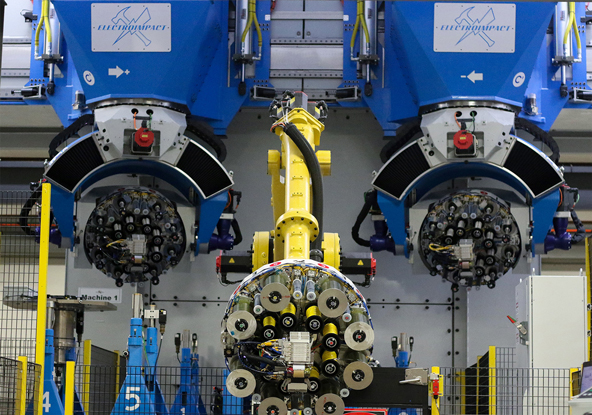

Electroimpact is an established world leader in the design and manufacturing of aerospace tooling and automation. It’s wide range of projects include complete automation assembly systems for commercial aircraft wings, riveting machines with tools for wing panel and fuselage assembly, both robotic and machined-based automatic fiber placement systems (AFPs), robotic drilling and assembly systems, and spacecraft handling equipment.

Used to produce large and complex composite parts for companies such as Boeing, Airbus, Bombardier, Embraer and NASA, AFP systems are highly technical and complex. Electroimpact continuously seeks to challenge current benchmarks and improve its machine designs, and in 2016 they achieved a quantum leap in performance, scale and precision of the AFP technology, with WITTENSTEIN Galaxie® system.

+49 7931 493-18860