- Extreme rigidity: high precision in medical or industrial robot

- High torque and overload capacity for safety purposes and high system robustness

- Small footprint: flexibility of system

- Easy replacement of existing strain wave or cycloid gearboxes due to output interface compatibility

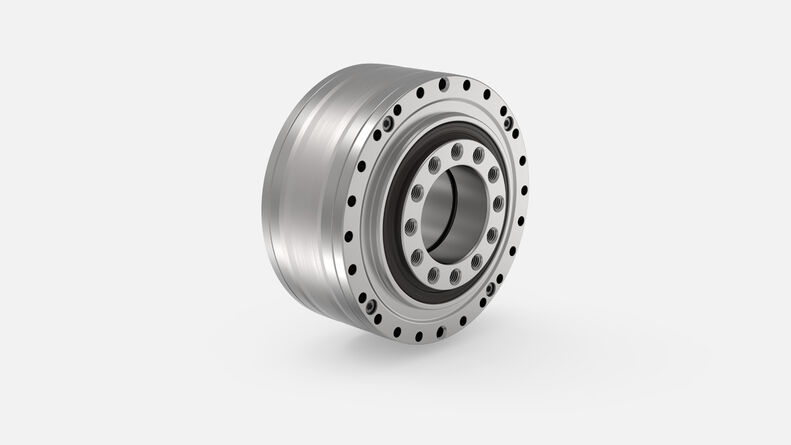

Galaxie® gearbox miniaturized

The most compact hollow-shaft gearbox with the highest torsional rigidity

With the miniaturized Galaxie®, we have taken the functional principle of our classic Galaxie® a step further. The result: innovative kinematics enabling almost full surface contact during power transmission – with an extremely compact footprint. Thanks to this unique concept, the miniaturized Galaxie® performs significantly better than established gearbox types with the same diameter in almost all dimensions. It combines the highest levels of rigidity, torque density and overload capacity with a very large hollow shaft and maintains zero backlash throughout its entire service life.

Downloads

- Flyer (2 MB)

- Data sheet SAG090 (157 KB)

- Data sheet SAG110 (148 KB)

- Technical data (CAD, dimension sheet, data sheet)

Your benefits

More precision due to:

- Extremely high rigidity

- Greater damping

- Higher machining precision

- Absolute zero backlash

Space and weight savings

- Downsizing of drive

- Upgrading of application with unchanged footprint

- Efficient use of hollow shaft

Maximum safety

- Safety reserves in case of overload

- Minimization of downtimes, e.g. due to broken cables in supplied media

Higher productivity

- Faster and more accurate positioning

- Reduced vibrations in system

- Minimized cable breakage

Ideally combined with the cyber® kit-line frameless motor from WITTENSTEIN cyber and with further on the market available hollow shaft motors. Connection to different standard servo systems by using specific adapter plate.

Big hollow shaft, eg. for wiring or for integrating media and / or components

Special tooth design for high gear ratios with almost complete surface contact