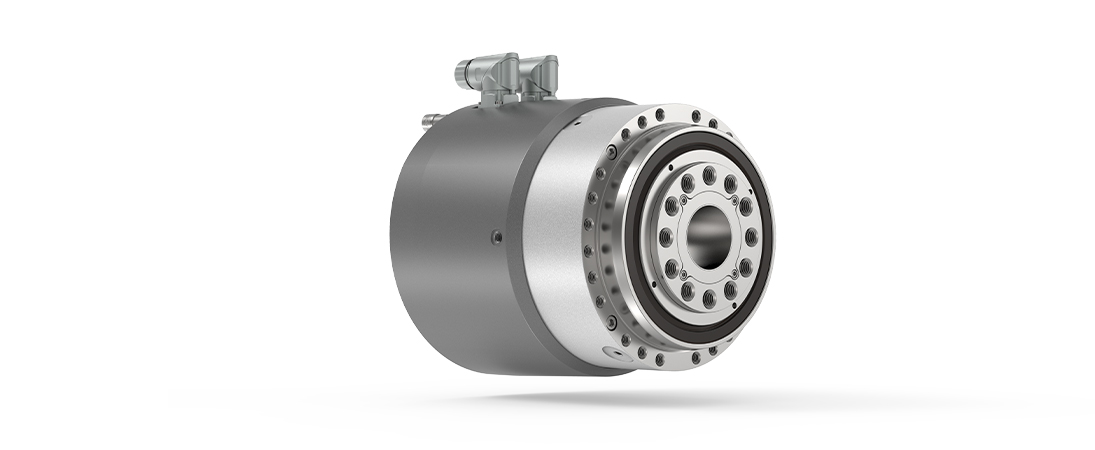

Compact hollow shaft gearmotor with same characteristics as gearbox version: zero backlash with highest torque density, torsional rigidity and positioning accuracy.

Advantages

- Highest torque density

Extreme torsional rigidity - Hollow shaft for efficient media supply

- Complete freedom from maintenance

- Improved synchronization accuracy

- Robust and precise output bearing

- Zero backlash

Benefits

- Programmable motion control

- Reduced costs for commissioning

- Increased productivity

- More stable processes

- New, high performance machine generations

- Greater competitiveness

| | | Galaxie® robustness line |

|---|

| Size | Unit | 85 | 110 | 135 | 175 |

|---|

| Variant | | D | D | D | D |

| Outer diameter1 | D [mm] | 144 | 187 | 211 | 263 |

| Hollowshaft diameter | d [mm] | 26 | 33 | 45 | 57 |

| Length2 | l [mm] | 197 | 232 | 240 | 325 |

Max. acceleration torque3 | T2B [Nm] | 450 | 1086 | 1800 | 4050 |

| Max. output speed3 | n2max [rpm] | 125 | 95 | 80 | 61 |

| Nominal output torque3 @ n2N | T2N [Nm] | 190 | 450 | 750 | 1685 |

| Nominal output speed3 @ T2N | n2N [rpm] | 31 | 23 | 20 | 15 |

| Emergency stop torque3 | T2Not [Nm] | 1350 | 3000 | 5400 | 12000 |

| Torsional rigidity3 | Ct21 [Nm/arcmin] | 160 | 370 | 650 | 1400 |

| Ratio4 | i | -24 |

Sizes of the Galaxie® accuracy line series on request

1 Without connectors/varies depending on mounting position

2 Without cooling connectors

3 Values are subject to variations

4 Negative ratio indicates output rotates in opposite direction to input.

Technical data valid for actuators with water cooling; data for convection cooling may vary.

Technical data for reference only

Note

Different encoder options, cooling options (liquid cooled, free convection), electrical connectors, and an optional holding brake are available depending on application requirements.

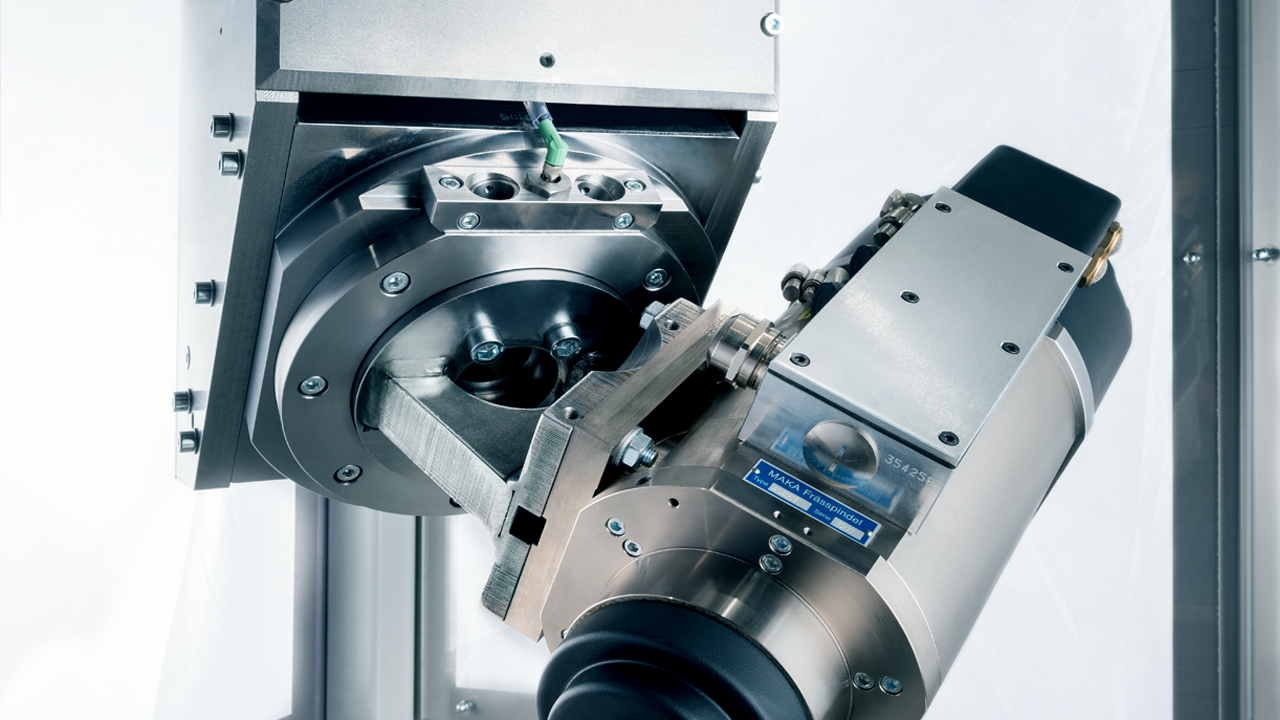

Typical applications

A/B/C Axis for precise positioning in CNC applications like milling and turning or indexing tables.