- Extreme rigidity: high precision in medical or industrial robot

- High torque and overload capacity for safety purposes and high system robustness

- Small footprint: flexibility of system

- Easy replacement of existing strain wave or cycloid gearboxes due to output interface compatibility

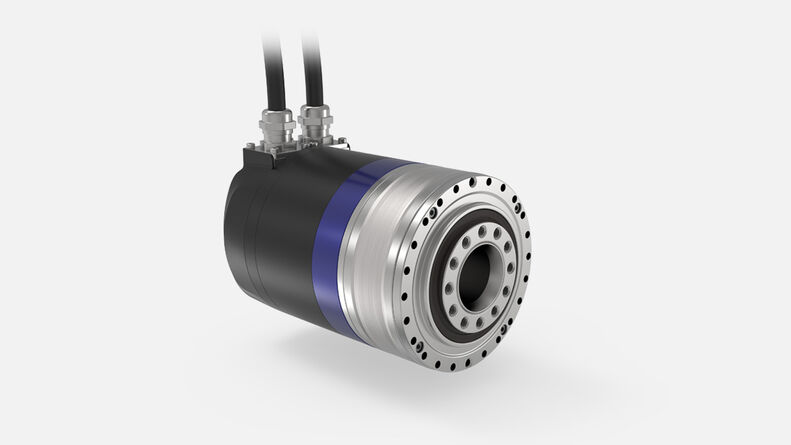

Galaxie® actuator miniaturized

Probably the most compact hollow shaft actuator with the highest rigidity

The highest levels of torque density and rigidity, excellent dampening properties, zero backlash and the largest hollow shaft – all of this is combined in the new miniaturized Galaxie® actuator from WITTENSTEIN SE, probably the most compact, all-in-one servo drive system of its kind. Thanks not least to its special overload capacity and torsional rigidity, it is perfect for surgical and high-precision robotics. The actuator’s performance parameters and features are individually configurable depending on the desired task – for instance the motor sizing, brake, connection to the application, power supply, electrical connection and feedback system – and it is also easy to integrate.

Downloads

- Data sheet SAGM090 (161 KB)

- Data sheet SAGM110 (161 KB)

- Flyer miniaturized Galaxie® actuator (4 MB)

Your benefits

More precision through

- Extremely high torsional rigidity

- Higher dampening

- Higher machining precision

- Absolute zero backlash

Space and weight savings

- Downsizing the drive train

- Upgrading the application without any increase in footprint

- Efficient usage of hollow shaft

Maximum safety

- Safety reserves in case of overload

- Minimization of downtimes due to e. g. broken cables in suppling media

Higher productivity

- Faster and more accurate positioning

- Reducing vibrations in the system

- Minimizing cable breakage due to higher bending radius