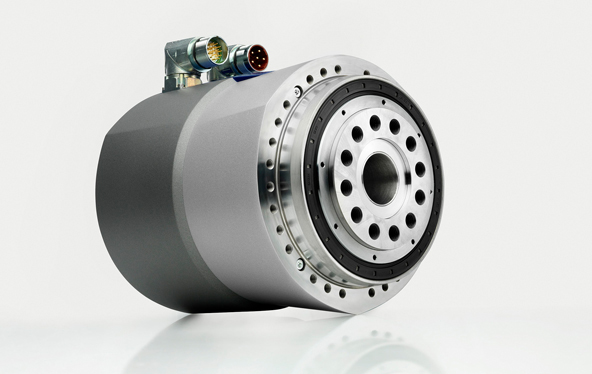

Zero backlash enables maximum precision

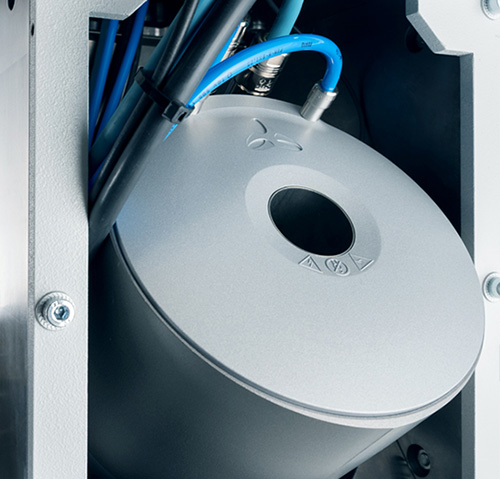

Freedom from backlash enables the very highest precision and quality as well as more rigidity for higher metal removal rates and innovative potential for future machine generations – the WITTENSTEIN Galaxie® Drive System creates a wealth of added value for MAKA, the German machine tool manufacturer of CNC equipment for machining wood, aluminum and carbon fiber composites. The Galaxie® also convinced the developers with its rapid and problem-free integration into a standard machine installed at a customer in Taiwan.

Galaxie® – tested and found to be sensational

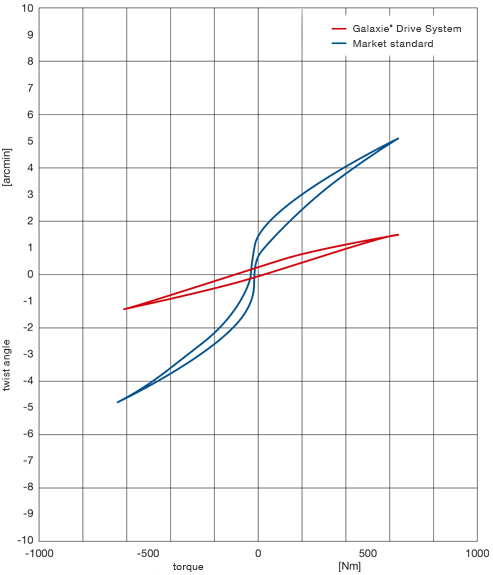

The outstanding performance compared to conventional drive systems first aroused the machine tool manufacturer’s curiosity early in 2016. In particular, it was the three to nearly six times better torsional rigidity of the completely backlash-free Galaxie® kinematics – depending on the benchmark – which persuaded MAKA to subject the Galaxie® to a trial on the test bed. The results were sensational and everything worked perfectly. The positive impression gained during the trial was further strengthened only a few months later, when the drive solution for a machine that had already been shipped to Taiwan had to be replaced by a Galaxie® Drive System. The intended improvement in performance was immediately confirmed. The prompt availability of the Galaxie® in the local regions is another important advantage.

Precision is the benchmark

To MAKA, precision breeds quality. Both the A and the C axis of the cutting head are constantly in motion. That’s why each individual axis has to be absolutely precise. The more backlash a drive has, the larger the contour tolerances – especially since the precision errors soon start to add up. MAKA was understandably tempted by the prospect of a drive system with zero backlash – the promise made by the Galaxie®.